Company

Safe packaging provider

History

Engas was established in 1990. Initially, the company specialised in the production of labels and simple packaging. Thanks to regular, annual investments in machinery park, the company grew to such an extent, it had to move to new production halls. It continued to acquire new customers, and, in 2004, it obtained financing for the purchase of a cold foiling machine for the production of packaging. In 2020. Engas further expanded its halls to accommodate a new production line. The company uses machines by renowned manufacturers, which are the leaders on the market, including KBA printing machines and Bobst die-cutting machines.

Process

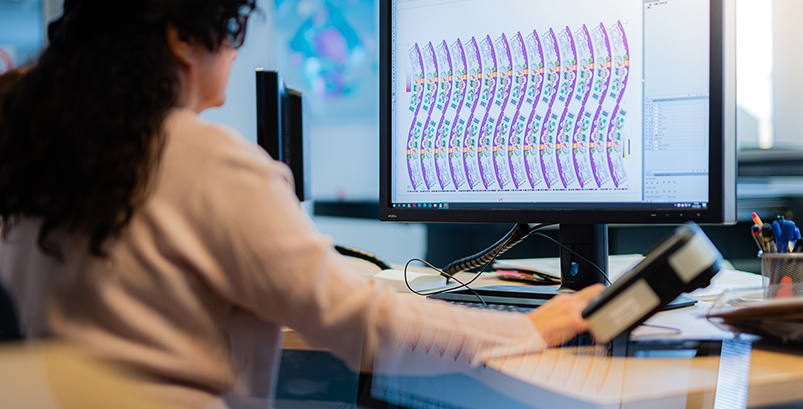

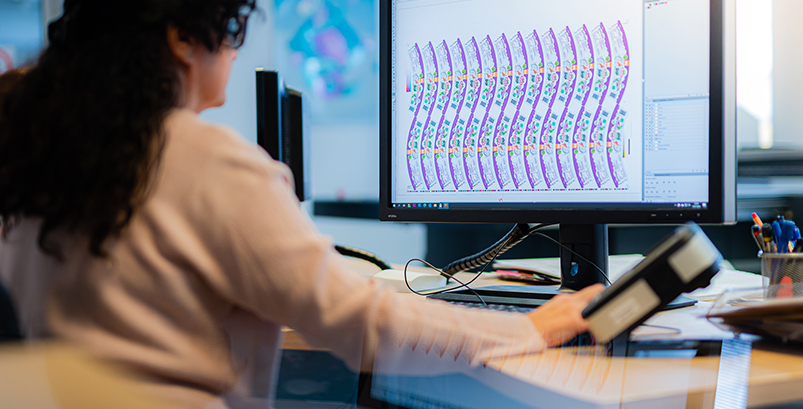

Design

The design is submitted by the customer, but due to the specific nature of the printing process, it undergoes additional technical processing by our specialists and is optimised for printing, which enables us to offer the best value for money.

Prototype

Once all aspects of the design have been agreed, we create a prototype of the packaging or cup to see how it will actually look like in real life. Then, the customer, supported by our quality department, makes a decision whether the product meets his or her requirements. Details that are often not visible and overlooked by non-specialists are corrected at this stage.

Production

Once the product has been approved by the customer, it passes through all the production departments in accordance with the quality procedures in place. Thanks to the experience of our operators, the final product meets all requirements of the customer.

Control

In order to ensure the top quality of the product, the packaging goes through an ex-post inspection process, where all items that do not meet the requirements of our quality department are rejected. The whole procedure allows to maintain a consistently high level of quality.

Certificates

Quality

We comply with the highest quality standards, meeting the rigorous criteria of the industry’s most important international certification bodies. We have been certified by FSC® and BRC, which is extremely important to ensure safety of food packaging. The company has also passed an ethical audit and has been implementing an environmentally friendly policy.

DANE

Engas Sp. z o.o.

Michała Grażyńskiego 351

43-300 Bielsko-Biała

Sąd Rejonowy w Bielsku-Białej

VIII Wydział Gospodarczy

Kapitał zakładowy: 3 045 000 zł

Nr BDO 000018535

Adres do e-doręczeń:

AE:PL-36086-77840-SGRVS-13

Company

Safe packaging provider

History

Engas was established in 1990. Initially, the company specialised in the production of labels and simple packaging. Thanks to regular, annual investments in machinery park, the company grew to such an extent, it had to move to new production halls. It continued to acquire new customers, and, in 2004, it obtained financing for the purchase of a cold foiling machine for the production of packaging. In 2020. Engas further expanded its halls to accommodate a new production line. The company uses machines by renowned manufacturers, which are the leaders on the market, including KBA printing machines and Bobst die-cutting machines.

Process

Design

The design is submitted by the customer, but due to the specific nature of the printing process, it undergoes additional technical processing by our specialists and is optimised for printing, which enables us to offer the best value for money.

Prototype

Once all aspects of the design have been agreed, we create a prototype of the packaging or cup to see how it will actually look like in real life. Then, the customer, supported by our quality department, makes a decision whether the product meets his or her requirements. Details that are often not visible and overlooked by non-specialists are corrected at this stage.

Production

Once the product has been approved by the customer, it passes through all the production departments in accordance with the quality procedures in place. Thanks to the experience of our operators, the final product meets all requirements of the customer.

Control

In order to ensure the top quality of the product, the packaging goes through an ex-post inspection process, where all items that do not meet the requirements of our quality department are rejected. The whole procedure allows to maintain a consistently high level of quality.

Certificates

Quality

We comply with the highest quality standards, meeting the rigorous criteria of the industry’s most important international certification bodies. We have been certified by: ISO 9001, PEFC i FSC® and BRC, which is extremely important to ensure safety of food packaging. The company has also passed an ethical audit and has been implementing an environmentally friendly policy.

Engas Sp. z o.o.

tel. 33 822-29-29

Fax 33 822-29-30

drukarnia@drukarniaengas.pl

Michała Grażyńskiego 351

43-300 Bielsko-Biała

NIP: 547-020-10-23

REGON: 270509881

KRS: 0000026928

Sąd Rejonowy w Bielsku-Białej

VIII Wydział Gospodarczy

Kapitał zakładowy: 3 045 000 zł